As all conversions done by me, under the banner of

Mac's Motoracing Models,

are "unique" so this will be slightly different to the last one.

Again I started this project using a

Minichamps Jordan 191, 1:18 scale Michael Schumacher "Donor"

car. This one supplied by Hilary. Again I started this project using a

Minichamps Jordan 191, 1:18 scale Michael Schumacher "Donor"

car. This one supplied by Hilary.

It was completely dismantled:

Removing one front wheel helps in the process, but is not

absolutely necessary. Care must be taken when removing the seat, front wheel

and steering

assembly so as not to break any parts. (Click on the Thumbnails to

enlarge the picture.)

As this is a Minichamps model,

the decals can be removed very

easily. Just lift the corner of

the decal with a modeling knife and peal off with a pair of

tweezers. Which is what I did for the large green ones on top of

the side pods. In a case like this there is no need for care in

removing them, so I used a piece of tape for

the others. easily. Just lift the corner of

the decal with a modeling knife and peal off with a pair of

tweezers. Which is what I did for the large green ones on top of

the side pods. In a case like this there is no need for care in

removing them, so I used a piece of tape for

the others.

As you can see, some of the "Decals" are not decals and are

painted on. These are easily removed with acetone (nail

polish remover) dipped "Q-tips". I am doing a couple

of extra things on this one so I decided to completely strip it

by letting it sit in a container of Lacquer thinners with a

paper towel draped over it, allowing the thinners to "wick"

through the towel and completely cover the body with the

thinners and fumes. It sat, with the lid on the container, for

approx. 60 minutes. I then removed it and washed off the loose

paint and removed the remainder with compressed air. easily removed with acetone (nail

polish remover) dipped "Q-tips". I am doing a couple

of extra things on this one so I decided to completely strip it

by letting it sit in a container of Lacquer thinners with a

paper towel draped over it, allowing the thinners to "wick"

through the towel and completely cover the body with the

thinners and fumes. It sat, with the lid on the container, for

approx. 60 minutes. I then removed it and washed off the loose

paint and removed the remainder with compressed air.

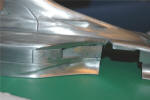

Some paint remained in the body lines, which I will

scrape out. I can also see what work was done, originally, at

the factory before the paint was applied. I will have to scribe

parts of the body lines again as they have been almost buffed

out in places. The front wing is going to

receive some re-working as well. Some paint remained in the body lines, which I will

scrape out. I can also see what work was done, originally, at

the factory before the paint was applied. I will have to scribe

parts of the body lines again as they have been almost buffed

out in places. The front wing is going to

receive some re-working as well.

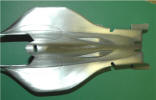

From

the bottom, you can see how, just the fumes of, the thinners

removed most of the paint. What is left will not matter as it is

out of site and will be painted over. From

the bottom, you can see how, just the fumes of, the thinners

removed most of the paint. What is left will not matter as it is

out of site and will be painted over.

After looking at my reference pictures, the front wing

needs to be reshaped. It has too much curve to it and the upper

winglets are wrong.

I have marked the wing, where I want to change it, and

here one I have marked the wing, where I want to change it, and

here one

side

of the rear is done. That is just the lighting that makes it

look like it is burned but it is not. side

of the rear is done. That is just the lighting that makes it

look like it is burned but it is not.

This

is the rough work done. The front edge is squared off and angled

more as it should be, not curved. For reference This

is the rough work done. The front edge is squared off and angled

more as it should be, not curved. For reference

I will also correct the bodywork at the side pods. It needs to

be cut back behind the radiators and fill the recess. Note to

anyone with the 191, the first three races the bodywork was like

this, USGP, Brazil and San Marino.

I started by grinding the top edge off the bodywork on both

sides

the recess will have to be filled. I will rough the inside of

the recess with a Dremel bit and then cut through completely to

the inside. I will then stick some "Scotch tape" on the outside

and fill the gap with some resin, then sand it all to the

correct shape.

the recess will have to be filled. I will rough the inside of

the recess with a Dremel bit and then cut through completely to

the inside. I will then stick some "Scotch tape" on the outside

and fill the gap with some resin, then sand it all to the

correct shape.

Just a little clean up inside required, then the final

re-shaping of the outside of the body. Then I will make

templates for the carbon fiber decals.

Just a little clean up inside required, then the final

re-shaping of the outside of the body. Then I will make

templates for the carbon fiber decals.

The initial reshaping is completed

rounded off the top edge

rounded off the top edge

and sanded each side.

and sanded each side.

A nice coat of primer will fill the small marks so I will have a

nice smooth finish to accept the semi-gloss black final

undercoat.

A nice coat of primer will fill the small marks so I will have a

nice smooth finish to accept the semi-gloss black final

undercoat.

After a few sessions of sanding, filling, sanding etc.

I screwed the body pieces back together so I could scribe the

panel lines, so they will line up when finally assembled. I will

pull it apart again for painting.

I screwed the body pieces back together so I could scribe the

panel lines, so they will line up when finally assembled. I will

pull it apart again for painting.

Next the front wing has a little more detail added to the upper

elements.

A little out of focus. I removed the metal element edges and

replaced it with 0.010" thick plastic flat strip attached to the

back edge with CA glue, then trimmed the height down slightly. I

still have to put the front of the angle in place, but I will do

that after it gets the base coat of black.

A little out of focus. I removed the metal element edges and

replaced it with 0.010" thick plastic flat strip attached to the

back edge with CA glue, then trimmed the height down slightly. I

still have to put the front of the angle in place, but I will do

that after it gets the base coat of black.

Final fill and sand

Final fill and sand

before it gets the Black semi-gloss undercoat.

before it gets the Black semi-gloss undercoat.

Update 8/30/09

It has been a little while, but I have done quite a bit since

your last visit.

The parts have all been painted in preparation for the carbon

decals.

The main body parts will be assembled prior to the application

of the carbon decals, to ensure the correct "line-up".

The main body parts will be assembled prior to the application

of the carbon decals, to ensure the correct "line-up".

It is always best to create your own templates for the carbon

decals; I use regular "painters masking tape" that you can get

at any hardware store, because it's flexible enough to stretch

and peels off easily. I apply the tape to the section I want and

then with a NEW model knife blade, cut the shape I want; peal it

off and stick it on a sheet of plane white paper.

I then mark the direction I want the weave of the carbon to flow. I

do this for all sections, then I scan the sheet with all the

templates on it.

You will see I have also marked a "Scale" on the sheet. That is

so I know I have the correct size, after it is scanned and saved

into Microsoft word. I lay it out in the way the Carbon weave

will flow, so I have an idea of how many sheets I will need.

You will see I have also marked a "Scale" on the sheet. That is

so I know I have the correct size, after it is scanned and saved

into Microsoft word. I lay it out in the way the Carbon weave

will flow, so I have an idea of how many sheets I will need.

The suspension "bumps" in the bodywork are too severe to really

expect the carbon decals to follow the contour without tearing,

so I cut a small piece of carbon decal in a diamond shape and

split the bottom in the middle, from the middle of the decal.

You can see it applied here

aligning it perfectly is not really a concern as you will see

later except to have it at approx. 45 degrees. Once those parts

are done I apply decals in a different place all together. It

will be 24 hours before I go back to the engine cover allowing

time for the decal to set more permanently.

aligning it perfectly is not really a concern as you will see

later except to have it at approx. 45 degrees. Once those parts

are done I apply decals in a different place all together. It

will be 24 hours before I go back to the engine cover allowing

time for the decal to set more permanently.

Here you see the decals applied to the tub section with the

vertical flow of the carbon

I had previously done the left side

I had previously done the left side

When applying the decal on the air-box, it important to know

where the "bump" in the bodywork is and cut a slot in the decal

prior to soaking it. While the decal is sitting in the water I

give the part a coat of Micro Sol and then mix in some water

with a brush, I find this a better solution than using Micro

Set. It allows me to move the decal to the exact position I

want, with less likelihood of accidental movement. You do have

to be careful though not to damage other decals already in

place. You can barely notice the split in the decal over the

bump if you get it right. You would if you did not apply the

small decal at 45 degrees.

When applying the decal on the air-box, it important to know

where the "bump" in the bodywork is and cut a slot in the decal

prior to soaking it. While the decal is sitting in the water I

give the part a coat of Micro Sol and then mix in some water

with a brush, I find this a better solution than using Micro

Set. It allows me to move the decal to the exact position I

want, with less likelihood of accidental movement. You do have

to be careful though not to damage other decals already in

place. You can barely notice the split in the decal over the

bump if you get it right. You would if you did not apply the

small decal at 45 degrees.

It's Sunday now and I can apply the right side air-box decal

The important part here is matching up the decal on the left

side as well as the "bump" on the body. Once I have the decal

where I want it I brush a coat of "Micro Sol" over it, to get it

to adhere to the contours, before using the hair drier. I then

use the hair drier for approx. 30 seconds. With a NEW knife

blade in my modeling knife, a BIG magnifying glass, and the

steadiest hands I can have, I start at the middle of the spine

and very carefully, with a very low angle of cut, drag the knife

blade to the end, then turn it around and do the same thing in

the opposite direction. I then carefully remove the cut pieces

with a pair of tweezers. Luckily the blade did not catch and I

am happy with the result

The important part here is matching up the decal on the left

side as well as the "bump" on the body. Once I have the decal

where I want it I brush a coat of "Micro Sol" over it, to get it

to adhere to the contours, before using the hair drier. I then

use the hair drier for approx. 30 seconds. With a NEW knife

blade in my modeling knife, a BIG magnifying glass, and the

steadiest hands I can have, I start at the middle of the spine

and very carefully, with a very low angle of cut, drag the knife

blade to the end, then turn it around and do the same thing in

the opposite direction. I then carefully remove the cut pieces

with a pair of tweezers. Luckily the blade did not catch and I

am happy with the result

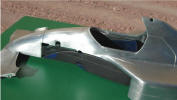

It's not easy to photograph, but that is what I call a good

result. The green in the picture is just the reflection of the

green background. In this picture you can clearly see the joint

on the "bumps" as well.

It's not easy to photograph, but that is what I call a good

result. The green in the picture is just the reflection of the

green background. In this picture you can clearly see the joint

on the "bumps" as well.

With the Right side done, I moved back to the top of the left

side-pod. I applied the decal in exactly the same manner. It is

difficult to see the joint

which is what you want. I know it's a little difficult to see in

that picture but looking more closely you will see two

seems/joints

which is what you want. I know it's a little difficult to see in

that picture but looking more closely you will see two

seems/joints

The one just to the right of the slot on the left and the second

just to the left of the same slot.

The one just to the right of the slot on the left and the second

just to the left of the same slot. The

rear wing is almost completed, but I did not take any pictures

of that, maybe for the next update. Small

Update 9/7/09

I have applied more carbon decals to the lower side of the side

pods and to the nose area of the cockpit.

You can see the direction of the carbon is mirrored on each side

of the damper pocket. Its beginning to look more like it should

now

of the damper pocket. Its beginning to look more like it should

now

Front wing and nose next..

Front wing and nose next.. To view just the

pictures click here |